Low Pressure Injection

Overview

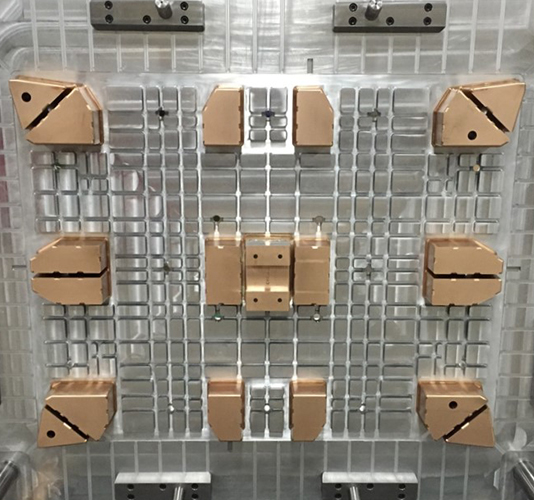

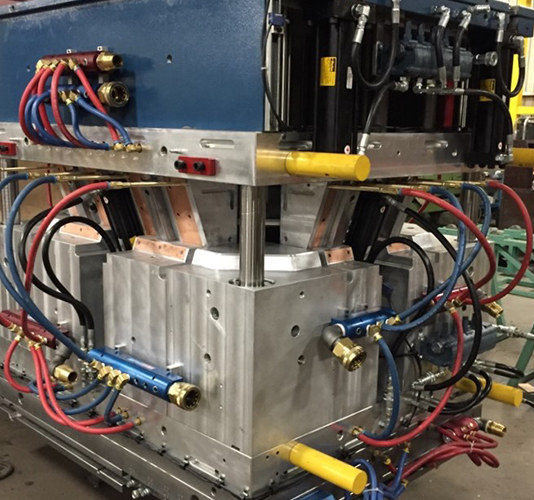

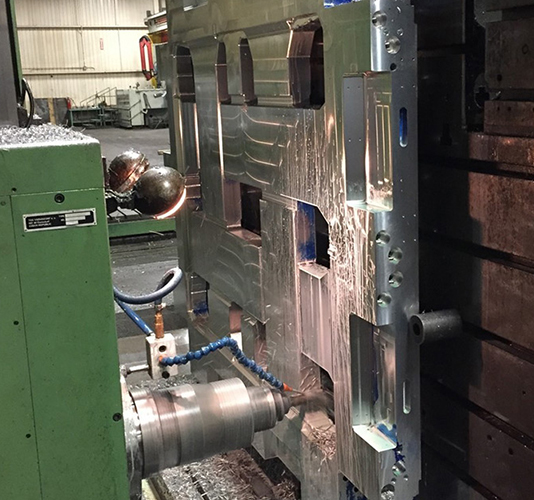

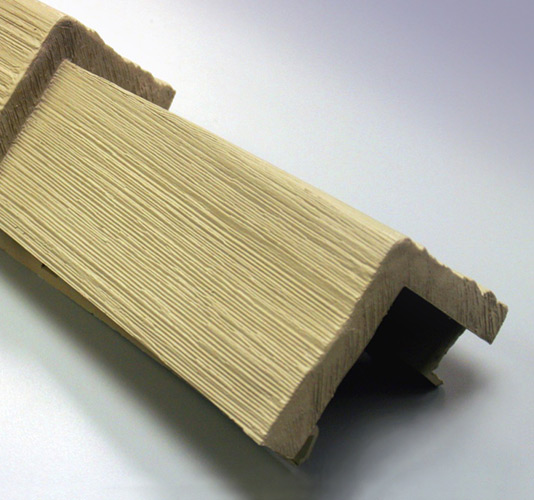

FGL specializes in innovative structural foam tooling. Structural foam molds are engineered with aluminum cores and cavities, designed to minimize cycle times and maximize production rates. Molds can be designed up to 170” x 100” and 90,000lb with multiple cavities and inserts. Our customers encompass many industries including material handling, construction and recreational products.

KEY BENEFITS

Expedited Delivery

Aluminum cores & cavities allow for faster machining & shorter lead times

Design Flexibility

Family molds, with multi-cavity designs

Size

Larger molds, lower clamp tonnage presses

Investment

Lower costs, with aluminum cores & cavities, no hot-runners required